About Us

About Us

Jui Kuang Enterprise Co.,Ltd.

WE ARE GOOD PARTENERS

Team work is the most important element in winning, to achieve “TRIPLE-WINNING” philosophy-customers satisfaction employees happiness and subcontractors pleasure, we link these three partners on the same boat, we solve the problems together. Grow hand in hand and create the mutual prosperous future. Whenever you want to be one of our partners, please don’t hesitate to contact us immediately, we’re here to welcome you with open arms.

WE CARE EVEN SMALL THING

To keep the cold forming machines and floor of the forming area CLEAN is a difficult even impossible job in this field. However, we have been particularly concerned about every detail since established; this is a small thing, but you can smell and image what company JUI KUANG is.

WE DO IT ALL FOR YOU

To pursue INHERENT QUALITY. We link our suppliers. Subcontractors and employees together into our quality control system; and keep inculcating and educating them to strengthen and upgrade their quality concept. Besides, we do a series of strict inspections to secure it.

PRODUCION AND Q. C. FLOW CHART

- MATERIAL INCOMING (I. Q. C. BY Q. C. DEPARTMENT)

- FORMING (SELF INSPECTION BY OPERATOR)

- DEGREASING (PROCESS INSPECTION BY Q. C. DEPARTMENT)

- PACKING (TURNING / TAPPING / HEAT TREATMENT / PLATING)

- SHPG. INSPECTION BY Q.C. DEPARTMENT

- SHIPPING

Lot no: how to read the lot no: month day machine no. drum no.

We do LOT NO CONTROL, in case, it is necessary to trace back all records in every production process.

COLOR MANAGEMENT:

To extinguish the material grade, we paint the different colors on the steel wire, also, apply on our work sheets and PE bags, To avoid mixing parts, we delimit the defects and scrap area with outstanding red line.

To ensure producing good quality products all the time, our operators enforce SELF INSPECTION strictly-random sampling 20 pcs every half hour, and recording the results.

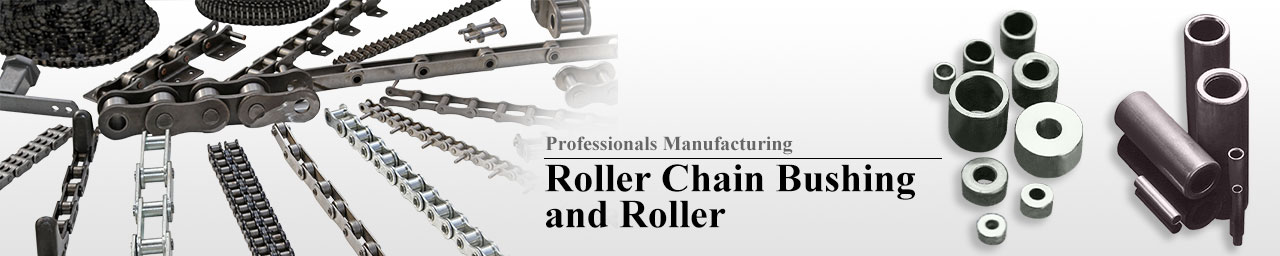

WE DO WHAT YOU NEED

A large variety of products enable you to have ONE STOP SHOPPING JUI KUANG has been trying the best to do the things ( excellent quality good service on time delivery and reasonable price ) right If you link JUI KUANG into your supplying chain system, you do the right thing.

PROFILE

- ESTABISHED IN May 2001

- CAPITAL: NTD$24,000,000

- REVENUE: NTD$60,000,000

- FACTORY AREA: 3000m2

- EMPLOYEES: 45

- PRODUCTIVITY: outside diameter: 47mm max. length: 100mm max.

- MATERIAL: carbon steel , stainless , aluminum and brass

MAIN PRODUCTS: a variety of solid bushings and solid rollers of transmission chains for bicycles, motorcycles, car timing chains, industrial transmission chains and conveyor chains etc., and a variety of nuts and cold formed parts

HISTORY

Forerunner was Fang Chang enterprises, established in 1973, was a specializing manufacturer of connecting and links for chains.

-

1985

Till Jun 1985 company reorganized and changed the name as JUI KUANG Besides, started using the SAN SHING cold forming machine to produce chain component-solid roller.

-

1993

In 1993, have lined up a wide range of solid rollers to supply for chains of timing (05/06B) ﹑BICYCLE (408/410) ﹑motorcycle (420/428, 08B/415) ﹑industry (40/41/50, 10B/60, 12B/80, 16B/100, 20B/120/140, 24B/160/32B/200) ﹑conveyor (2042/2052/2062/2082/2102/2122) and agriculture (CA550, 555, 557/S45/S55…)

-

1995

We devoted ourselves to the development of solid bush, throughout almost a year research and test, we successfully developed it, and became the 1st one maker can submit solid bush in TAIWAN. After kept several years developing, we are now the only one maker in TAIWAN can provide a whole series of solid bushes.

-

1996

Reached a 60% market share of solid rollers business in TAIWAN domestic market. And started developing the international market to expand our sales network.

-

1997

Successfully developed perfume bottle lids, and got s good response from customer, now, patent is applying. Also, developed many other cold formed parts for bicycle ﹑motorcycle ﹑automobile….

-

1998

Moved the plant into the current location-Kuei Jen, in order to smooth the production process and increase the production capacity for rapid growth of international demand.

-

1999

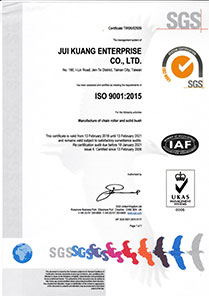

Following ISO9002 guidelines to strengthen our quality system.

-

2002

QS-900 certified by S. G. S.

-

2009

ISO9001 certified by S. G. S.

-

2017

ISO9001:2008 certified by S. G. S.